Pull-out Strength

The key feature of Helix® is the TWISTED profile. This drives the failure mechanism from a frictional mode to untwisting, setting Helix® apart from other fibers. Helix® behaves more like conventional steel reinforcement than other fibers because of this mechanism.

This 'untwisting' requires six times more pull out force compared with a non-twisted steel fiber of equivalent area. Furthermore Helix® maintains a constant resistance regardless of how far it has been untwisted. This differs from other fibers that fail when the cross sectional area is reduced as the fibers pull out of the concrete.

Furthermore the pull-out resistance of Helix® is not dependent on the inclination angle of the micro rebar with respect to a crack.

For more detailed technical information, go to the manufacturer's website: Helix Steel.

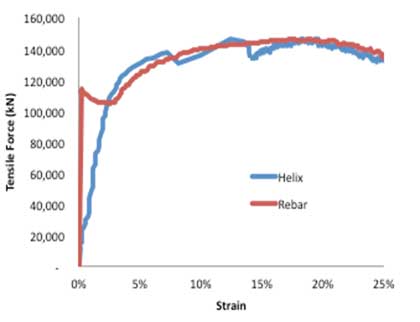

Stress Strain Curve

The graph to the right compares the stress strain curve of Helix® to conventional steel reinforcement. Note that with rebar the stress increases with minimal strain until the first dominant crack occurs (at about 120,000 kN). At this point there is a drop in stress, and a large increase in the strain (from 0% to approximately 5%), as the rebar engages and starts to resist the load.

Helix® begins to engage soon after loading as micro-cracks form in the concrete. This behavior may be attributed to the short development length of Helix®: 1/4” compared with 24” for 15M rebar. Therefore the strain in the Helix® reinforced concrete can be seen to increase gradually with increasing stress. This improves the performance of the concrete and prevents the formation of a single dominant crack.

Equivalence to Rebar

The bending moment capacity and shear strength of Helix® reinforced concrete is dependent on the dosage in the concrete. Dosage is measured in pounds per cubic yard or kilograms per cubic meter.

For example, consider a 6" thick concrete wall with #4 bar at 20" on center in both directions. Substituting a Helix® dosage of 20 lbs/yd3 will achieve:

- Bending moment capacity: 16.7 kip-in/ft. (16.7 kip-in/ft. for rebar)

- Shear strength: 8.5 kip/ft. (3.0 kip/ft. for rebar), a 186% improvement

- First crack strength: 512 psi (493 psi for rebar), a 4% improvement

- Durability, toughness: 122 lb.-in/ft. (99 lb.-in/ft. for rebar), a 23% improvement

Determination of Dosage and Ordering

The procedure for determining the correct dosage and ordering from your ready mix supplier is as follows:

- Send Fab-Form your concrete structural drawings or concrete thickness & strength along with the rebar schedule using this ONLINE FORM.

- Fab-Form determines the correct dosage (as engineered by Helix)

- You submit this dosage to your ready mix supplier(s) to get a quote for the Helix fiber in your concrete

- If your ready mix supplier does not have experience with Helix, give their name to us and we will arrange training

- If you require an engineered and sealed equivalence letter, our engineers Wicke Herfst Maver Consulting Inc. will review the Helix® design and provide this letter for a fee of approximately $350

Wicke Herfst Maver Consulting Inc.

Wicke Herfst Maver Consulting Inc. have been conducting due diligence on Helix® since late 2012, researching the many tests and corroborating with other engineers across North America. They are well qualified to answer any technical questions you may have. Call (604)484-2859 or visit www.whmengineers.com.

Helix Calculator

Use this calculator for simple slab on grades. Click on the image to the right to use the calculator.

For foundation walls, the dosage will be affected by the location of the rebar within the wall and it is highly recommended to get the dosage engineered. Send us your structural drawings and we will get the dosage engineered at no cost.

Physical Properties

- Material: cold drawn steel wire, zinc galvanized

- Length: 1" (25 mm)

- Configuration: rectangular cross section twisted five times along axis

- Cross sectional area: 0.0003 in2 (0.196 mm2)

- Weight: 0.00141 oz. (0.0401 gm.) per micro bar

- Steel tensile: 245 ksi (1,700 MPa)

- Micro bar tensile: 66.2 poundforce (294.5 N) each

- Modulus of Elasticity: 29,000,000

Packaging (Metric)

- Cardboard boxes

- Weight: 10 kilograms

- Dimensions: 34cm x 28cm x 19cm H

- Micro bars/box: approximately 250,000

- Skid packaging

- 8 layers, 12 boxes per layer, 96 boxes per skid

- Weight: 960 kilograms net, 1,018 kilograms gross

- Dimensions: 107cm x 107cm x 163cm H